PF Duct Measurements

Background

When large quantities of dust are pneumatically conveyed and distributed, the question of the distribution of mass flows and particle sizes in the system often arises. Knowledge of these operating parameters is essential for optimum utilisation of the system components – such as mills, firing or dosing systems.

In dust firing systems, for example, it is important to optimally coordinate the firing and grinding systems. Only with a well-matched system is it possible to reduce

- nitrogen oxide emissions

- residual combustion

- combustion air volumes to a minimum

Furthermore, if the quantities of carrying air, fuel flow and particle sizes in the individual ducts are known, it is possible to

- check the effects of wear on the grinding tools

- check the carrying gas velocities in the dust ducts to prevent deposits in the ducts or backfire from the burner

- avoid hot spots in the combustion chamber

- increase flame stability, especially in the minimum load range

- control the wall atmosphere of the combustion chamber

The Pulverized Fuel Measuring Device PFM 3.0

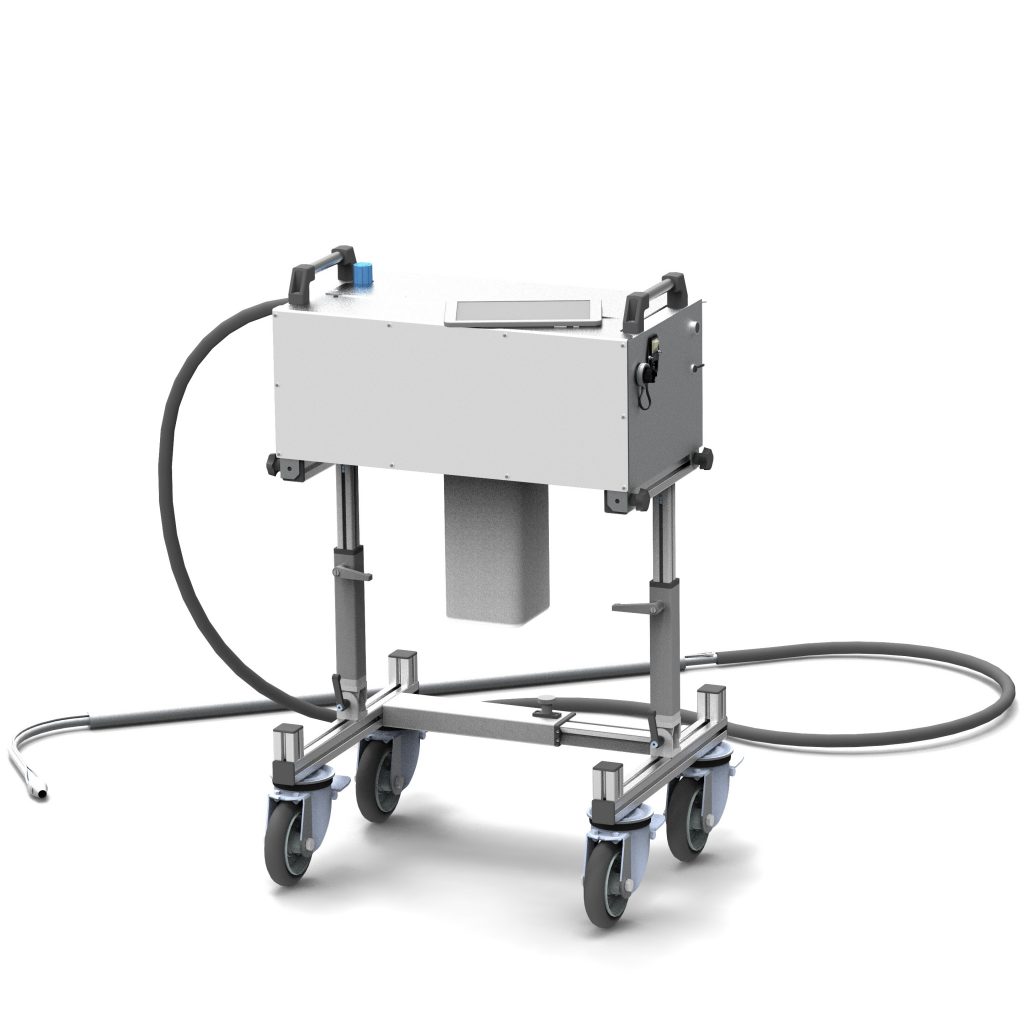

Pulverized Fuel Measuring Device PFM 3.0

The mobile measuring device PFM 3.0, developed by heat and power engineering, measures pneumatically conveyed dusts according to the standard described in VGB R123 C/2.9. The possible materials are fuels for dust combustion plants such as biomass, hard coal and lignite, but also raw materials such as lime or cement. The range of particle size is from a few µm up to 5 mm.

The measuring instrument is characterised by a compact design with low weight and high performance. Through its unique ergonomics and intuitive user interface it is ideal for 1-person operation – even in difficult measuring environments. Further advantages are the high degree of automation, which leads to fast measurement results, as well as the toolless assembly and disassembly and the good accessibility for cleaning and maintenance. Via a USB interface, the measurement results can be easily transferred to Excel on your own computer.

With the PFM 3.0 measuring device, information can be obtained in a short time in a largely automated process about

- dust and air distribution within one burner level

- dust and air distribution within a duct

- flow velocity within a duct

- fuel/air ratio

- temperature distribution within the duct

- ropes

- static pressure in the duct

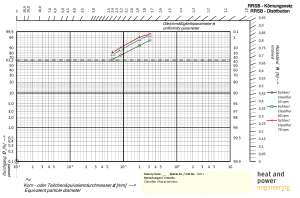

- particle size distribution and oversize particles

The Measurement Procedure

The PFM 3.0 can be set up and connected to the power and compressed air supply toolless within a few minutes.

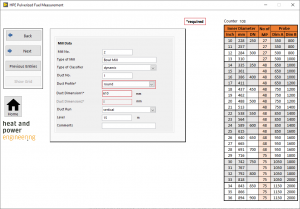

After setting the measuring parameters into the tablet, a special zero pressure probe is inserted through the measuring port into the dust duct. A compressed air-operated measuring lock prevents the fuel dust from escaping from the duct into the environment. The PFM 3.0 uses a compressed air ejector to suck a partial flow isokinetically from the pipe. For this purpose the PFM 3.0 automatically regulates a zero pressure between the dust duct and the probe. In the measuring device, the fuel dust is separated from the carrying gas flow by means of a cyclone and is continuously weighed in a container. The partial flow quantity is extrapolated to the total raw mass flow by the control unit. The cleaned carrying gas is guided over a Prandtl probe and thus the carrying gas flow as well as the load and the velocity are determined at each measuring point.

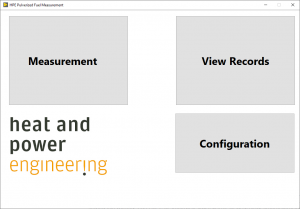

User Interface

The individual measuring points within the duct are specified by a perforated disc. The operator only has to move to the individual measuring points, everything else is done by the control unit in the PFM 3.0. Measuring point changes are indicated optically by an LED light. Alternatively, it is possible to use the automatic probe traversing unit developed by heat and power engineering.The capacity of the dust container is big enough that emptying is usually only necessary after the measurement has been completed. The measurement of a dust duct with a diameter of 400 – 700 mm takes only about 10 minutes with the usual 48 measuring points.

The particle size distribution of the sample can be determined after the measurement using the sieve method.

The Evaluation

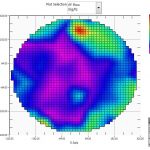

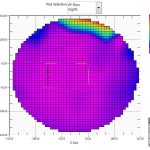

When the measurement is finished, the PFM 3.0 immediately displays the results and saves them; including all individual results. Outliers can be detected immediately and individual measuring points as well as the entire duct can be measured again, if necessary. Heatmaps show the distribution of fuel dust and air within the duct. After the measurement campaign, the results can be transferred to a USB stick and loaded on your own PC using an Excel macro and, if necessary, processed further.

Dust distribution in the duct cross section: inconspicuous (left) and distinct stranding (right)

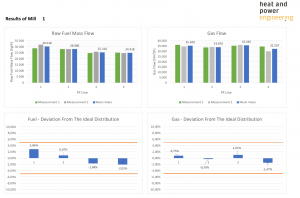

Results of a dust measurement

If you are interested in the dust monitor PFM 3.0 please contact us. We will be pleased to make you an individual offer.

Measuring Services

heat and power engineering offers the following services:

- Planning and execution of dust measurements according to VGB R123 C/2.9

- Measurement and operating data analysis

- Operational optimizations

Measuring Equipment

In our webshop you can obtain components for your dust measurements around the clock.

Deutsch