Measurements

Measurement equipment

For standard measurement like pressure, temperature or volume flow as well as for specialized measurement like oxygen or cole mass flow: heat and power engineering has the appropriate equipment. If required, we are also developing individual measuring probes, as often needed in industrial-scale plants.

For the manual measurement of gases up to 500 °C in the low pressure range, we use hot-wire and cup anemometers manufactured by Höntzsch, as well as dynamic pressure anemometer manufactured by Airflow.

For oxygen measurement we have a measuring probe manufactured by J. Dittrich at our disposal.

Furthermore, we can also access the equipment of our partners, as required, e.g. gas analysis equipment for the determination of oxygen, carbon dioxide, carbon monoxide, nitrogen oxide, or for the ultrasonic measurement of vapour.

For pulverized coal measurement (mass flow and grain size distribution) we are using the measurement device SMG 10 manufactured by Schallert.

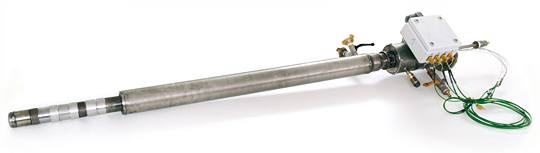

Corrosion probe

The determination of corrosion dynamics and rates is part of an evaluation of corrosion damage in combustion plants. This requires a tempered relocation of substrate specimens into the predominant flue gas environment.

The life time of evaporator and superheater pipes has a crucial effect on the economic feasibility of refuse incinerators or coal boilers. The major part of plant shutdowns can be attributed to pipe damages in this context. The testing of novel materials or the feeding of additives in the flue gas is cost-intensive, tedious and prone to failure. Process and plant modifications can be implemented only at high expenses, if at all.

Due to the aforementioned reasons, we developed a temperature controlled corrosion probe for the temporary exposition of tubular specimen. This was done in close collaboration with the Institut für Verfahrenstechnik und Dampfkesselwesen (IVD) of the University of Stuttgart.

Tubular samples of various test materials can be mounted in the probe head and exposed up to 1.5 m deep in the vessel. The specially designed air cooling enables a very homogeneous radial and axial cooling.

Analytical choices

Energy dispersive X-ray spectroscopy (EDX)

A comparative determination of material qualities for the respective flue gas environment can be achieved by subsequent material analyses. The corrosion grade is being optically identified by a scanning electron microscope. Back-scattered electron images and EDX/WDX X-ray analyses are available for the scaling evaluation. In addition, the operational parameters of the boiler are being evaluated in view of the confirmability of the results.

References (corrosion probe)

Vattenfall Europe Generation AG & Co. KG

Expositions at 525 – 720 °C

Scaling examination

E.ON Kraftwerke GmbH

Expositions at 575 – 625 °C

Testing of corrosion resistant superheater materials

RWE Power AG

Expositions at 520 – 560 °C

Testing of corrosion resistant superheater materials

Deutsch