Air Load Control

Increasing demands from grid operation demand load profiles that were not intended in the design of many coal blocks. Essential requirements are the shortening of the arrival and departure times and more frequent part-load trips. This results in changes in the air load guide, so that continued safe operation is guaranteed and at the same time the life of the internals and units is not affected as possible.

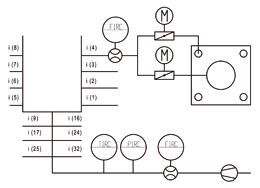

In the course of a pilot-plant replacement of a 500 MW hard coal block, the engineering firm Hellmick and Pfeiffer supported the operator in the optimization of the air load guidance. To improve combustion, the air control on the burners was switched from a guide through the staged air to a shroud air duct. The jacket air represents approx. 80% of the combustion air converted at the burner. The control of the shell air and a control of the total air requirement at the burner via the staged air therefore contribute to long-term flame stability.

In addition, an improved pressure and temperature correction of the combustion air supply was developed and imported into the control technology. This made it possible to set the air requirement on the single burner more precisely.

The implementation of the air load control in large combustion systems must satisfy all aspects of safe operation management. In all operating conditions – from cold start with oil fire to partial load and full load with various coals up to the safe shutdown of the block – the air control has to ensure an optimal air supply to the burner.

Increasing demands from grid operation require load profiles that were not intended in the design of many coal-fired power plants. Essential requirements are the shortening of start-up and shut-down times and more frequent part-load operation. This results in changes in the air load control, so that safe operation is still guaranteed and at the same time the lifetime of components and assemblies is not affected.

In addition, the state-of-the-art changes over the life cycle of a power plant. The integration of a new control technology with extended process control options or modifications to the burners to reduce emissions or corrosion may also require modifications to the air load control system.

In the course of a SCADA retrofit of a 500 MW hard coal unit, heat and power engineering supported the operator in the optimization of the air load control. To improve combustion, the air control on the burners was changed from a guide through the staging air to sheath air. The sheath air represents approx. 80% of the combustion air converted at the burner. The control of the sheath air and a control of the total air requirement at the burner via the staging air thus contribute to flame stability.

In addition, an improved pressure and temperature correction of the combustion air supply was developed and imported into the control system. This made it possible to set the air requirement of a single burner more precisely.

Deutsch