Air and Load Control

The air and load control of large combustion plants has a direct impact on emissions, corrosion, burnout, operation mode under load changes, flexibility in fuel use and formation of heat shifts in the boiler. The prerequisites for optimum operation are a reliable airflow measurement and an adequate trimming of the combustion air.

The need for fuel and air rebalancing often results from changes in boundary conditions since initial operation of the boiler, e.g. from changed fuel compositions, modifications or stricter emission limits. Missing or non-reliable measurements make the rebalancing more difficult.

Incomplete combustion increases emissions and leads to expensive corrosion damage to evaporator and superheater pipes. The high proportion of residual carbon has the consequence that the ashes can not be recycled, but must be disposed of in a cost-intensive manner.

Too high values for fuel/ air-ratio at each burner cause efficiency losses. Excessive amount of air leads to an increased power consumption of the FD fan due to pressure losses at dampers or other installations. Fan operation at the design limits also reduces flexibility in daily operation.

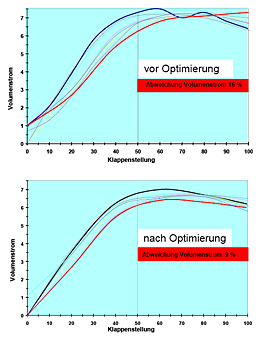

Usually, a blending of the combustion air at the burner on primary and secondary air is carried out in the form of air load curves. Technically, the trim is implemented by means of adjustable louvers. Targeted trim requires optimally adjusted damper mechanics and reliable airflow measurements.

Usually, trimming of the combustion air at the burner by means of primary and secondary air is carried out in the form of air load curves. Technically, the trim is implemented by means of adjustable dampers. Precise trimming requires optimally adjusted damper mechanics and reliable airflow measurements.

Substantial optimization potential in the field of firing therefore offers the standardization of the actuating functions of the burner air flaps. To ensure safe operating conditions, an adjustment of the flap mechanism is usually required when replacing actuators. An optimized design at this point leads to significant improvements in the furnace and stabilizes the boiler operation.

heat and power engineering has performed air measurements on large combustion plants such as incinerators and coal-fired power plants, and helped the operator to optimize the airflow. In addition to the analysis of measurement and operating data, CFD and process simulations are used as work equipment.

Deutsch